Overview

Strata Worldwide | Australia has a proven system to pneumatically transfer bulk quantities of stone dust from surface storage silos to trickle dusters at the longwall tailgate.

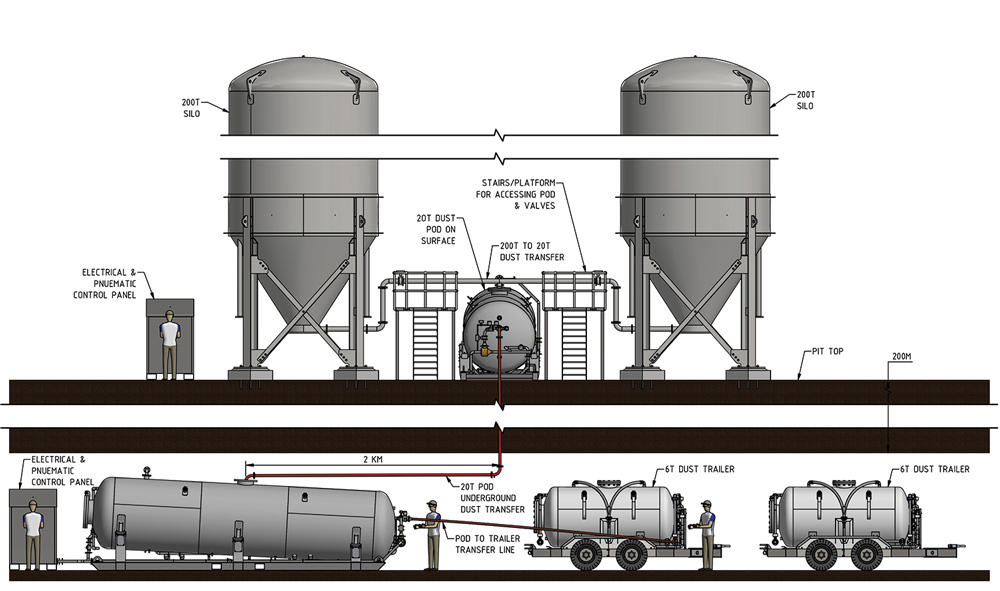

The surface silo is connected through a borehole to an underground 20-tonne POD, and the stone dust is pneumatically transferred through a dedicated, pressurised pipeline.

Trickle dusting at the longwall tailgate is remotely controlled from surface and underground locations, with the dispersal fully adjustable to maintain mine compliance with 85% / 15% TIC ratios.

Story

Moorlarben Coal Mine, located in the coalfields of the Mudgee Region of New South Wales, Australia was looking for a low maintenance, streamlined stone dusting system to reduce both time and manpower involved in stone dusting tasks. As with all longwall operations, the essential task of dusting in the longwall tailgate was their primary focus.

Beginning in late 2018, Strata Worldwide worked closely with mine personnel to design and integrate the Strata Automatic Stone Dust Storage and Dispersal System into the operation. The system is specifically designed to facilitate the transfer of bulk quantities of stone dust directly from road tankers, into a 150-tonne storage silo on the surface. Situated adjacent to a borehole, the stone dust is then pneumatically transferred underground and stored in a static 20-Tonne POD.

The 20-Tonne POD serves as an underground storage and filling station, transferring materials to mobile POD and flinger dusters as needed. It can also be used for manual hose dusting directly from the POD.

As the mine advances, the management team plans to extend the dedicated pipeline and install additional inline 20-Tonne PODs to work together to pneumatically transfer bulk quantities of stone dust inbye. The distance between the static PODs inline will be up to 3000 metres.

The transfer of stone dust between PODs can be done manually or set to occur automatically using Programmable Logic Controllers (PLCs). The transfer rate will be up to 16.2 tonnes per hour.

All inline PODs will be accessible for manual hose dusting, and the furthest inbye POD will be used as a storage and refill station for “local” mobile dusters.

The entire system is monitored live via SCART/CITEC and full operational and functional control can be accomplished via a PLC at the surface control center (CRO) or underground control center.

VARIETY & MOBILITY

From the 20-Tonne POD, Moorlarban Coal Mine has elected to utilise two trailer-mounted 6-Tonne Mobile Dusters to transport stone dust from the pipeline to the longwall tailgate. Here they provide up to 25 hours of continuous trickle dusting coverage. Neither the machine, nor personnel have to enter the tailgate to undertake trickle dusting activities. To-date, the system is successfully achieving dust transfers over distances up to 4.6km, supplying the tailgate with the required 150kg per hour of stone dust.

For other areas and routine tasks, these same 6-Tonne trailer-mounted POD dusters can function as manual hose dusters or bulk transfer pressure dusters. These are a one-of-a-kind multi-functional design which switches between modes by simply engaging a three-position joystick to select the option. The operator selects the required mode and the system automatically purges itself and resets, ready for the task. Display pressure gauges notify the operator when the system is ready, eliminating the need to adjust or check a manual regulator’s pressure by hand. At completion of the task the operator resets the joystick and the system purges and resets once again, ready for next operator or task selection.

This multi-functional design is also available in Strata’s 3-Tonne QDS PODs.

The mine’s management have expressed great satisfaction with the function and ease of use of the system and trailers.

“This system is very efficient, cost effective and is very easy to use. After 40 years in the coal mining industry, the ability to effectively manage and constantly apply stone dust to a high standard using leading edge technology is essential to the success of the Moolarben high performing, low-cost underground operation.” Steven Chandler | Underground Operations Manager “