On an Autumn day in 2020 in South Australia, a young worker at a salt facility reached over and wiped some debris off of the conveyor belt. In a fraction of a second, the fast-moving belt caught her sleeve, and the powerful mechanical force of the belt yanked her toward a pinch point, where her arm was caught. The victim suffered weeks of recovery and permanent injuries. Subsequently, the employer pleaded guilty to breaching the Australian Work Health and Safety Act for failing to provide a safe system of work, resulting in substantial fines and equipment upgrades.[1]

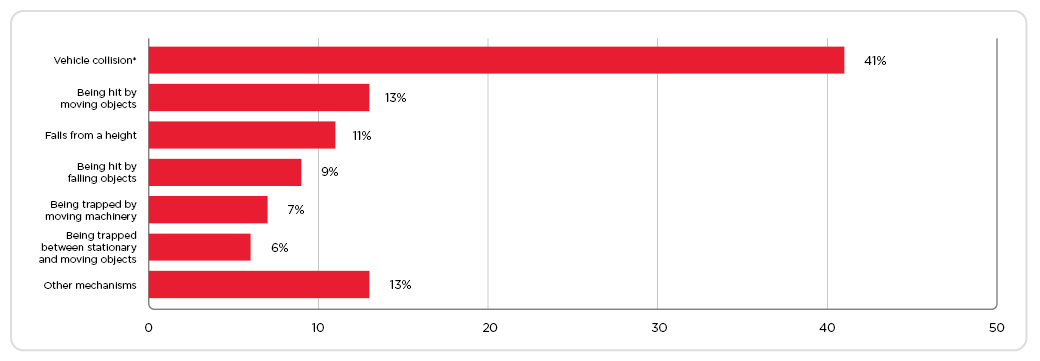

Incidental contact with industrial mining equipment is one of the most prevalent and life-changing injuries in the workplace.[Fig 1] Mining injuries stemming from breaking the safety plane (reach-in), entrapment between vehicles/objects, equipment/personnel collisions, etc. can be avoided using proximity detection technology like the HazardAvert Perimeter Guard™. In the case of the salt operation, once the Perimeter Guard’s personal alarm device worn by the worker was detected within the hazard zone, the belt would have immediately shut down, preventing the injury.

Figure 1 – The list of injuries is dominated by incidents that could be prevented by proximity detection technology.[2]

“Perimeter Guard is used to detect people or vehicles by running the field generating cable in a loop around a restricted area or piece of machinery,” explained Jacques Lubbe, Operations Manager, Strata Products Australia. “The patented design produces customized warning and hazard zones that are detected by receiver devices worn by the staff or installed on vehicles, and these generate audio and visual warnings. For improved safety, the system is agnostic and can be paired with Controller Area Network (CAN bus) systems to automatically halt or shut off equipment if the receiver is too close.”

Some examples of Perimeter Guard applications:

- Underground diamond drill rigs are sophisticated multi-directional excavating machines that use a boom and mast configuration. At any one time, up to 3 people can be working near the drill rig. With moving and rotating hydraulic components, the equipment inherently poses potential safety risks to the workers. The Perimeter Guard’s cable loop is installed to include the boom and mast extension of the rig, creating a hazard zone between 1.5-2 meters (5-6.5 ft) from the cable. These sizing configurations are custom and ensure that personnel are well outside of the hazardous areas while the equipment is operating. The system can be programmed to shut down the drill rig if a personal receiver is detected.

- Whether the units are mobile or static, feeder breakers and crushers that reduce boulders into aggregate in seconds can be deadly if safety precautions are not followed. Fatal incidents occur when personnel inadvertently get too close and accidentally get caught up in the chains and crushers. Or they see rolling or stuck cargo and feel compelled to help it along either with a tool or their hands. Perimeter Guard detection systems prevent tragic situations by automatically shutting the system down when close proximity and improper activities are detected.

- Berm accidents are prevalent in quarries, open-pit mines, landfills and construction sites. This is when large machinery approaches the edge of a roadway or work platform and the edge is sometimes unstable and gives way under the massive weight of the machine. Other times, the berm has a slump where a single wheel will fall off the edge, throwing off the balance of the equipment, and causing it to topple. These incidents are often fatal to the operator and a total loss to the equipment. Perimeter Guard can be placed along the edge, alerting the machinery operators to the distance.

- Conveyor belt safety zones are important because, along with reach-in injuries, workers have been known to pass underneath the belt as a shortcut or ride the belt into mine shafts or processing towers. The Perimeter Guard tracks and eliminates unsafe practices around conveyors.

An Invisible Fence for Workplaces or Gathering Areas

Perimeter Guard can be used for setting up permanent or temporary work zones or protected safe areas. These invisible fences can be used to keep machinery and vehicles either inside or outside of a designated area. Receivers installed on vehicles detect the electromagnetic zones and trigger warning alarms for the operators when in close proximity to the boundaries. The system can be paired with the vehicle CAN bus to automatically stop movement if the parameters are breached.

Creating Restricted Zones

At some worksites, there are areas where only specifically trained and certified staff are allowed to enter. When paired with a proximity detection software platform, the Perimeter Guard system can identify the personal receiver and logs the unauthorized activity. This data can be used later to identify safety exposures and opportunities for training.

“The alerts and data collection improve workplace safety compliance, mitigate costly incidents, reduce liability, and make operations more efficient,” Lubbe concluded.

Reference

[1] Wondracz, Aiden. Pacific Salt worker Courtney Herbert arm dragged conveyer belt company fined 75000. Wayalla, South Australia. Aug 2022. https://www.dailymail.co.uk/news/article-11111751/Pacific-Salt-worker-Courtney-Herbert-arm-dragged-conveyer-belt-company-fined-75-000.html

[2] Staff. Key work health and safety statistics. Safe Work Australia. Canberra, AU. Sept 2022. https://www.safeworkaustralia.gov.au/resources-and-publications/statistical-reports/key-work-health-and-safety-statistics-australia-2021